You want your vehicle to perform at its best, so you need solutions that fit your needs. Custom flexible exhaust pipe designs help you achieve a precise fit and greater durability.

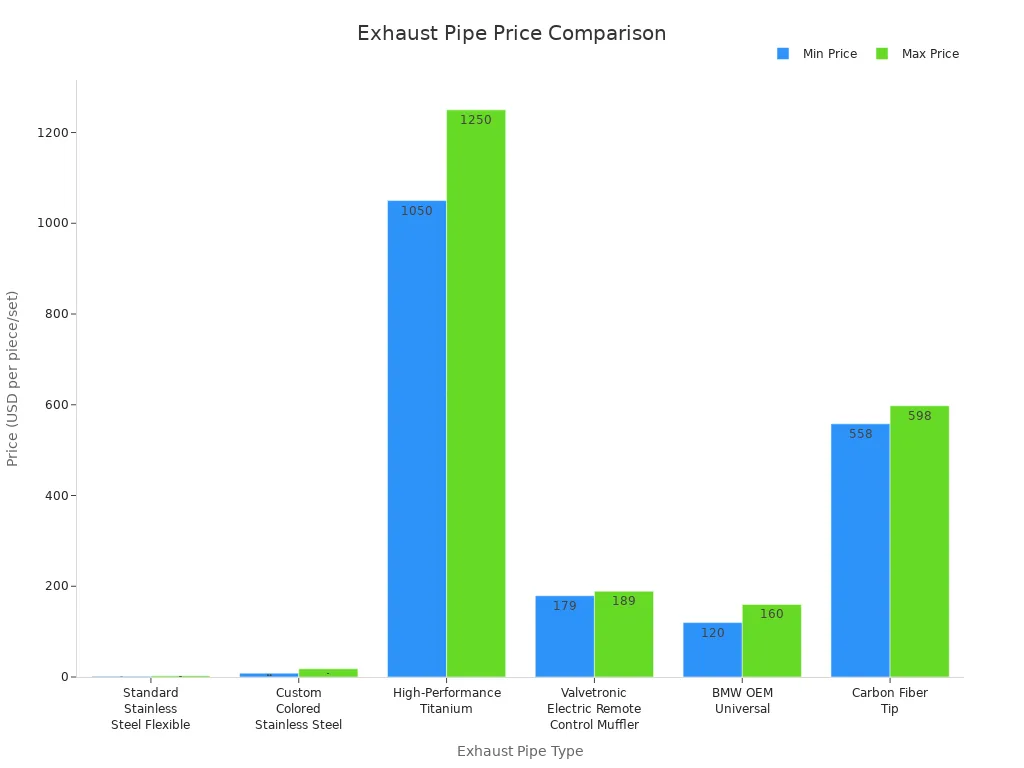

The table below highlights key advantages over standard options:

| Aspect | Summary |

|---|---|

| Durability | High-quality stainless steel resists heat, vibration, and corrosion for longer service. |

| Fit and Installation | Flexible design adapts to different models, making installation of a turbocharger pipe or turbocharger oil line much easier. |

| Performance Benefits | Lower backpressure means better efficiency and reduced emissions. |

| Cost-effectiveness | Fewer replacements and less downtime save you money. |

Key Takeaways

- Custom flexible exhaust pipes improve engine power, efficiency, and durability by fitting your vehicle perfectly and using high-quality materials like stainless steel.

- Working with experienced manufacturers and following industry standards ensures your exhaust system is reliable, safe, and meets environmental rules.

- Proper installation and regular maintenance keep your exhaust pipe working well longer, saving you money on repairs and boosting performance.

Why Customization Matters for Flexible Exhaust Pipe Performance

Enhancing Engine Efficiency and Power

You want your engine to deliver maximum power and efficiency. Customizing your flexible exhaust pipe helps you achieve this goal. When you use a system designed for your vehicle, you get smoother exhaust gas flow. Mandrel bends keep the pipe diameter consistent, which reduces backpressure. This lets your engine expel gases faster and increases horsepower and torque. Upgrading to high-quality materials like stainless steel or titanium also improves durability and the power-to-weight ratio. Recent research shows that custom exhaust setups, such as those with flexible thermoelectric generators, can boost output power by over 25%. These changes help your engine run more efficiently and improve fuel economy.

Meeting Unique Vehicle and Market Requirements

Every vehicle has different needs. Custom flexible exhaust pipes let you match those needs exactly. You can choose the right pipe diameter, shape, and material for your application. This is important for special vehicles like heavy-duty trucks, industrial machines, or performance cars. Custom fabrication ensures a perfect fit, even for complex designs. You can also select sound profiles and finishes that match your preferences. Precision CNC tube bending removes kinks and turbulence, which improves throttle response and drivability. Many customers notice immediate gains in power and smoother operation after installing a custom system.

Improving Durability and Reducing Maintenance Costs

You want your exhaust system to last and require less maintenance. Customization lets you pick materials like stainless steel or aluminized steel, which resist corrosion and heat. This means your flexible exhaust pipe will last longer, even in tough conditions. A well-designed system reduces the risk of leaks and failures, so you spend less time and money on repairs. By investing in a custom solution, you get reliable performance and lower long-term costs.

6 Steps to Achieve Better Results with Flexible Exhaust Pipe Customization

Assess Your Specific Requirements

Start by identifying what your application needs from a flexible exhaust pipe. Every vehicle or system has unique demands, so you should consider several factors before making a decision:

- Choose materials that match your temperature and pressure requirements. Stainless steel works best for high heat and pressure.

- Make sure the pipe’s temperature and pressure ratings fit your system for safety and reliability.

- Check compatibility with your vehicle or equipment to avoid leaks or malfunctions.

- Decide on the right installation method—clamps, flanges, or welds—based on pipe type and movement.

- Think about maintenance and how long you want the pipe to last.

- Balance cost with durability and long-term savings.

- Select the right structural type, such as single or double-layer corrugation, and consider protective layers like mesh or braid for extra durability.

- Match the size and connection method (length, diameter, flange, welding, clamp) for a safe and effective fit.

- Consider the environment—temperature, vibration, and dynamic loads all affect performance.

- Work with a reputable manufacturer for quality and support.

Tip: A clear understanding of your requirements leads to a safer, longer-lasting, and more cost-effective solution.

Choose the Right Materials and Manufacturing Processes

Selecting the right materials and manufacturing processes directly impacts the performance and lifespan of your flexible exhaust pipe. Stainless steel, especially grade 304, is the top choice for high-performance applications because it resists corrosion, handles high temperatures, and maintains strength over time. Mandrel bends keep the pipe’s diameter consistent, which helps maintain airflow and engine efficiency. Proper welding techniques, such as using matching filler rods and argon gas purging, create strong, corrosion-resistant joints.

Flexible pipe couplings help your system absorb vibrations, manage thermal expansion, and correct misalignments. These features prevent cracks and leaks, extending the life of your exhaust system. Quality assurance, including fatigue testing and compliance with standards like ASTM and ISO, ensures your pipe meets durability and reliability benchmarks. Environmental factors—like exposure to heat, moisture, and chemicals—make corrosion resistance and fatigue strength essential. Regular inspections and proper installation also play a big role in maximizing lifespan.

Work with Experienced Flexible Exhaust Pipe Manufacturers

Partnering with an experienced manufacturer gives you access to advanced equipment, skilled workers, and technical expertise. These manufacturers select corrosion-resistant materials, design pipes with the right diameter and flexibility, and ensure the system absorbs vibrations and handles thermal expansion. This reduces the risk of cracks, leaks, and damage to other components.

You also benefit from easier installation, better customization options, and reliable after-sales support. Effective communication and problem-solving skills from your manufacturing partner help you achieve a durable, high-performing exhaust system. Look for manufacturers with a strong track record, modern R&D centers, and a commitment to quality and innovation.

| Certification/Standard | Description/Significance |

|---|---|

| ISO 9001 | Quality management systems for consistent product quality |

| IATF 16949 | Automotive quality management standard |

| ISO 14001 | Environmental management standards |

| RoHS | Restriction of hazardous substances compliance |

| ASME | Mechanical engineering and manufacturing standards |

Note: Choosing a manufacturer with these certifications ensures your flexible exhaust pipe meets industry standards for quality, safety, and environmental responsibility.

Ensure Compliance with Industry Standards

You must ensure your flexible exhaust pipe complies with all relevant industry standards and regulations. In the United States, the EPA enforces strict emissions standards under the Clean Air Act. Your exhaust pipe must also meet noise, emissions, and durability norms to comply with vehicle safety and environmental rules.

Key standards include:

- ASME B31.3 for process piping (material, design, welding, testing)

- ASME B31.1 for power piping (industrial and power plant applications)

- ASME Section IX for welding qualifications

- ISO 10380 for international flexible metal hose standards

- BS 6501 Part 1 for British standards

Manufacturers use high-performance materials like stainless steel, aluminized steel, and carbon steel to meet these requirements. Some systems now include sensors for real-time diagnostics, helping you stay compliant and competitive.

Focus on Proper Installation

Proper installation is critical for optimal performance and long-term durability. Use mandrel-bent piping to maintain the interior diameter around bends, which reduces restrictions and heat buildup. Position the flexible exhaust pipe close to the engine to dampen vibrations and prevent stress on the system. Assemble exhaust sections from the headers toward the tailpipe, using ball flange connectors for tight seals.

- Make tight joints and mark connections for accurate alignment.

- Use clamps and V-band connections for modular sections, allowing easy removal or replacement.

- Plan the exhaust exit location and select the right tips for your system.

- Include resonators or mufflers as needed, keeping local sound regulations in mind.

Improper installation—such as over-tightening or poor alignment—can damage the pipe’s sealing and flexibility. This leads to reduced efficiency and premature wear. Always follow best practices or consult a professional installer.

Plan for Ongoing Maintenance and Support

Regular maintenance keeps your flexible exhaust pipe performing at its best. Leading manufacturers offer support services such as:

- Visual inspections for cracks, leaks, or loose connections.

- Identifying wear signs like rust or heat damage.

- Guidance on cleaning to avoid damaging protective coatings.

- Applying rust-preventive sprays or coatings.

- Recommendations for heat protection, such as shields or wraps.

- Advice on avoiding road hazards that can damage the system.

- Scheduling regular professional maintenance as part of vehicle servicing.

- Support for upgrading or replacing damaged pipes.

Manufacturers with strong R&D and service teams provide OEM and aftermarket support, ensuring you get the most from your investment.

Remember: While custom solutions may cost more upfront, they deliver better performance, longer lifespan, and lower maintenance costs, offering a strong return on investment.

By following these six steps, you ensure your flexible exhaust pipe delivers top performance and durability. Customization gives you a real advantage:

- Leading manufacturers offer drawing-based customization, rapid prototyping, and high on-time delivery, driving strong customer retention.

- Digital engineering tools and tailored designs help you meet unique temperature and pressure needs.

| Key Aspect | Details |

|---|---|

| Market Size (2024) | USD 1.2 Billion |

| CAGR (2026-2033) | 5.5% |

| Market Drivers | Emission regulations, innovation |

Consult experienced manufacturers to achieve the best results for your next flexible exhaust pipe project.

FAQ

What materials work best for custom flexible exhaust pipes?

Stainless steel offers excellent heat resistance and durability. You can also choose aluminized steel for cost savings. Both materials perform well in automotive applications.

How do you ensure a perfect fit for my vehicle?

You provide your vehicle’s specifications or drawings. The manufacturer uses advanced CNC bending and forming equipment to create a pipe that matches your requirements.

How often should you inspect your flexible exhaust pipe?

- Inspect every six months.

- Look for cracks, leaks, or corrosion.

- Schedule professional maintenance if you notice any damage.

Post time: Aug-11-2025