Maintaining the Turbocharger Pipe 11427844986 is crucial for ensuring optimal engine performance. These pipes play a vital role in channeling compressed air, which enhances power delivery and improves throttle response. Using the best tools for servicing this component can significantly impact its efficiency and lifespan. Proper tools not only streamline the maintenance process but also help prevent potential issues, ensuring that the turbocharger operates at its best.

Key Takeaways

- Use the right wrenches for servicing. Open-end, box-end, and adjustable wrenches each serve specific purposes.

- Select appropriate socket sizes for turbocharger maintenance. Common sizes include 10mm, 13mm, and 17mm.

- Calibrate torque wrenches regularly. Proper torque prevents leaks and mechanical failures.

- Choose the right type of pliers for the task. Slip-joint, needle-nose, and locking pliers each have unique benefits.

- Inspect the Turbocharger Pipe every 5,000 miles or six months. Regular checks help catch issues early.

- Use effective cleaning methods based on engine type. Wet cleaning suits four-stroke engines, while dry cleaning is best for two-stroke engines.

- Identify signs of wear for timely replacements. Look for discoloration, surface pitting, and excessive play in connections.

- Incorporate inspection cameras for thorough maintenance. They provide visual access to hard-to-reach areas and help document findings.

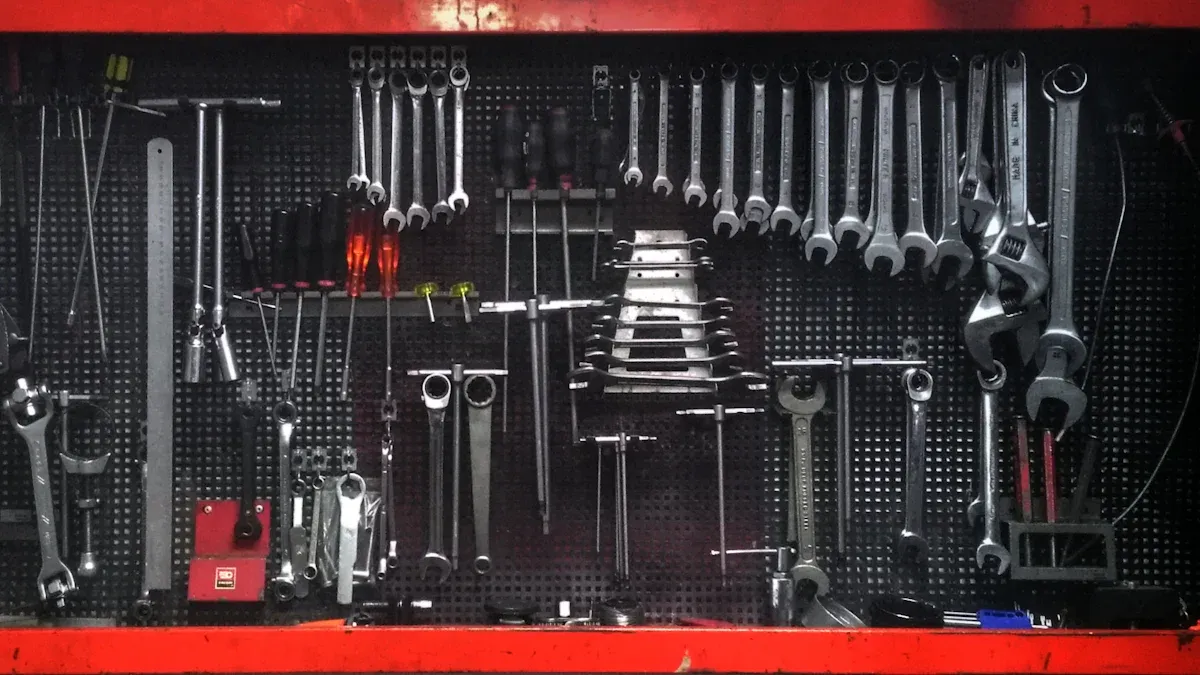

Essential Tools for Turbocharger Pipe 11427844986 Maintenance

Wrenches

Types of Wrenches

Wrenches are fundamental tools for servicing the Turbocharger Pipe 11427844986. They come in various types, each designed for specific tasks. The most common types include:

- Open-End Wrenches: These wrenches have a U-shaped opening that fits over the nut or bolt. They allow for quick adjustments but may slip if not used carefully.

- Box-End Wrenches: These feature a closed loop that grips the nut or bolt securely. They provide better torque and reduce the risk of rounding off fasteners.

- Adjustable Wrenches: These versatile tools can accommodate different sizes of nuts and bolts, making them ideal for various applications.

Usage Instructions

When using wrenches, ensure a proper fit on the fastener to avoid damage. Always pull the wrench towards you rather than pushing it away. This technique provides better control and reduces the risk of slipping. Regularly inspect wrenches for wear and replace any that show signs of damage.

Socket Sets

Recommended Sizes

Socket sets are essential for servicing the Turbocharger Pipe 11427844986. A comprehensive set typically includes sizes ranging from 8mm to 24mm. Commonly used sizes for turbocharger maintenance include:

- 10mm: Often used for smaller bolts.

- 13mm: Commonly found in turbocharger assemblies.

- 17mm: Frequently used for larger fasteners.

How to Use Effectively

To use socket sets effectively, select the appropriate socket size for the fastener. Attach the socket to a ratchet handle for ease of use. When tightening or loosening bolts, apply steady pressure and avoid sudden jerks. This approach minimizes the risk of stripping the fastener.

Torque Wrenches

Importance of Torque

Torque wrenches are critical for ensuring that fasteners are tightened to the manufacturer’s specifications. Proper torque prevents issues such as leaks and mechanical failures. Over-tightening can lead to stripped threads or damaged components, while under-tightening may result in loose connections.

Calibration Tips

Regular calibration of torque wrenches is essential for accurate measurements. Follow these tips for effective calibration:

- Check Manufacturer Guidelines: Refer to the manufacturer’s instructions for specific calibration procedures.

- Use a Calibration Tool: Employ a torque calibration tool to verify accuracy.

- Store Properly: Always store torque wrenches in a relaxed state to maintain their calibration.

Neglecting maintenance of the Turbocharger Pipe 11427844986 can lead to significant risks. Regular inspections help identify issues like oil leaks and performance drops. Ignoring these checks can escalate into costly repairs, including turbocharger bearing replacements. Investing in quality tools for servicing ensures that the turbocharger operates efficiently, ultimately saving money in the long run.

Pliers

Types of Pliers

Pliers are versatile tools essential for servicing the Turbocharger Pipe 11427844986. They come in various types, each serving a specific purpose. Here are some common types of pliers used in turbocharger maintenance:

- Slip-Joint Pliers: These pliers feature an adjustable pivot point, allowing users to grip objects of different sizes. They are ideal for holding and turning nuts and bolts.

- Needle-Nose Pliers: With their long, slender jaws, needle-nose pliers excel at reaching tight spaces. They are perfect for manipulating wires and small components within the turbocharger assembly.

- Locking Pliers: Also known as Vise-Grips, these pliers can lock onto an object, providing a secure grip. They are useful for holding components in place during repairs.

Best Practices for Use

To maximize the effectiveness of pliers, follow these best practices:

- Choose the Right Type: Select the appropriate pliers for the task at hand. Using the wrong type can lead to damage or ineffective results.

- Maintain a Firm Grip: Ensure a secure grip on the object being manipulated. This prevents slipping and reduces the risk of injury.

- Avoid Excessive Force: Applying too much force can damage both the pliers and the component. Use steady, controlled pressure instead.

Screwdrivers

Types Needed

Screwdrivers are another essential tool for servicing the Turbocharger Pipe 11427844986. Various types of screwdrivers cater to different fastener heads. Here are the most commonly used types:

- Flathead Screwdrivers: These have a flat blade and are suitable for slotted screws. They are often used in various automotive applications.

- Phillips Screwdrivers: Featuring a cross-shaped tip, Phillips screwdrivers provide better grip on screws. They are commonly found in turbocharger assemblies.

- Torx Screwdrivers: These have a star-shaped tip and are increasingly used in modern vehicles. They offer superior torque and reduce the risk of stripping screws.

Proper Handling Techniques

Proper handling of screwdrivers ensures safety and efficiency. Consider the following techniques:

- Use the Correct Size: Always select a screwdriver that fits the screw head snugly. This prevents slipping and potential damage to the screw.

- Apply Even Pressure: When turning screws, apply consistent pressure. This technique helps avoid stripping the screw head.

- Keep Tools in Good Condition: Regularly inspect screwdrivers for wear. Replace any that show signs of damage to maintain effectiveness.

Specialized Tools for Turbocharger Pipe 11427844986

Pipe Cutters

Choosing the Right Cutter

Selecting the appropriate pipe cutter is essential for servicing the Turbocharger Pipe 11427844986 effectively. Various types of pipe cutters exist, each designed for specific applications. Here are some factors to consider when choosing a cutter:

- Material Compatibility: Ensure the cutter can handle the material of the pipe, whether it is aluminum, steel, or plastic.

- Size Range: Select a cutter that accommodates the diameter of the pipe. Many cutters can handle a range of sizes, making them versatile.

- Ease of Use: Look for cutters with ergonomic designs. A comfortable grip allows for better control and reduces fatigue during extended use.

Cutting Techniques

Proper cutting techniques enhance the effectiveness of pipe cutters. Follow these steps for optimal results:

- Mark the Cut: Use a marker to indicate where the cut will occur. This ensures precision.

- Secure the Pipe: Clamp the pipe in place to prevent movement during cutting.

- Apply Steady Pressure: Rotate the cutter around the pipe while applying consistent pressure. This technique creates a clean cut without damaging the pipe.

Hose Clamps

Types of Hose Clamps

Hose clamps play a crucial role in securing hoses to fittings in the Turbocharger Pipe 11427844986 system. Various types of hose clamps are available, including:

- Screw-Type Clamps: These clamps use a screw mechanism to tighten around the hose. They provide a secure fit and are easy to adjust.

- Spring Clamps: These clamps automatically adjust to the hose diameter. They are ideal for applications where frequent removal is necessary.

- Ear Clamps: These clamps feature a unique design that provides a strong grip. They are often used in high-pressure applications.

Installation Tips

Installing hose clamps correctly ensures a leak-free connection. Consider these tips:

- Positioning: Place the clamp at least one inch from the end of the hose to allow for a secure fit.

- Tightening: Use a torque wrench to tighten screw-type clamps to the manufacturer’s specifications. Avoid over-tightening, which can damage the hose.

- Inspection: Regularly check hose clamps for signs of wear or corrosion. Replace any that show damage to maintain system integrity.

Vacuum Pumps

Importance in Maintenance

Vacuum pumps are vital for maintaining the Turbocharger Pipe 11427844986. They help remove air and moisture from the system, preventing contamination. Proper maintenance of the turbocharger relies on effective vacuuming to ensure optimal performance.

Operating Instructions

To operate a vacuum pump effectively, follow these guidelines:

- Setup: Connect the pump to the system securely. Ensure all connections are tight to prevent leaks.

- Power On: Turn on the pump and allow it to run until the desired vacuum level is reached. Monitor the gauge for accurate readings.

- Shutdown: Once finished, turn off the pump and disconnect it from the system. Store the pump in a dry place to prevent damage.

Inspection Cameras

Benefits of Inspection

Inspection cameras serve as invaluable tools for servicing the Turbocharger Pipe 11427844986. They provide several benefits that enhance maintenance efficiency and accuracy:

- Visual Access: These cameras allow technicians to see hard-to-reach areas within the turbocharger system. This visibility helps identify issues that may not be apparent through standard inspection methods.

- Real-Time Feedback: Technicians receive immediate visual feedback during inspections. This capability enables them to make informed decisions quickly, reducing downtime.

- Documentation: Inspection cameras can record video and capture images. This documentation serves as a reference for future maintenance and can assist in diagnosing recurring issues.

- Cost-Effective: By identifying problems early, inspection cameras can help prevent costly repairs. Addressing issues before they escalate saves both time and money.

How to Use Effectively

Using inspection cameras effectively requires following specific guidelines to maximize their benefits:

- Choose the Right Camera: Select a camera with appropriate features, such as adjustable lighting and flexible cables. These features enhance visibility in tight spaces.

- Prepare the Area: Clear any obstructions around the inspection site. This preparation allows for easier maneuvering of the camera.

- Inspect Methodically: Move the camera slowly and methodically through the turbocharger system. This approach ensures thorough coverage and helps capture any potential issues.

- Review Footage: After the inspection, review the recorded footage carefully. Look for signs of wear, leaks, or other abnormalities that may require attention.

- Document Findings: Take notes on any issues discovered during the inspection. Documenting findings aids in planning necessary repairs or replacements for the Turbocharger Pipe 11427844986.

By incorporating inspection cameras into the maintenance routine, technicians can enhance their ability to service the Turbocharger Pipe 11427844986 effectively. These tools not only improve the inspection process but also contribute to the overall longevity and performance of the turbocharger system.

Maintenance Tips for Turbocharger Pipe 11427844986

Regular Inspection

Frequency of Checks

Regular inspections of the Turbocharger Pipe 11427844986 are essential for maintaining optimal performance. Technicians should conduct these checks at least every 5,000 miles or every six months, whichever comes first. Frequent inspections help identify potential issues before they escalate into costly repairs.

What to Look For

During inspections, technicians should focus on several key areas:

- Leaks: Check for any signs of oil or coolant leaks around the pipe connections.

- Cracks or Damage: Inspect the pipe for any visible cracks or signs of wear that could compromise its integrity.

- Clamps and Fasteners: Ensure that all clamps and fasteners are secure and free from corrosion.

- Hoses: Examine hoses for signs of wear, such as fraying or bulging.

Cleaning Techniques

Recommended Cleaning Solutions

Cleaning the Turbocharger Pipe 11427844986 is vital for maintaining its efficiency. The following table outlines effective cleaning methods based on engine type and frequency:

| Cleaning Method | Engine Type | Frequency of Cleaning | Key Considerations |

|---|---|---|---|

| Wet Cleaning | Four-stroke | Every 50 to 200 hours | Reduce engine load to below 430°C before cleaning; wait for cooling and drying to prevent thermal stress. |

| Dry Cleaning | Two-stroke | Every 25 to 50 hours | Use granules injected with compressed air; ensure airflow passages are clear. |

| Compressor Cleaning | Both | Every 25 to 100 hours | Clean when engine is running at 25-85% load; allow engine to dry for at least five minutes post-cleaning. |

Step-by-Step Cleaning Process

To clean the Turbocharger Pipe effectively, follow these steps:

- Preparation: Disconnect the pipe from the turbocharger and any associated components.

- Choose a Cleaning Method: Select either wet or dry cleaning based on the engine type and condition.

- Apply Cleaning Solution: Use the appropriate cleaning solution and method as outlined in the table.

- Rinse and Dry: If using a wet cleaning method, rinse thoroughly and allow the pipe to dry completely before reinstallation.

- Reassemble: Reconnect the pipe and ensure all connections are secure.

Replacement Guidelines

Signs of Wear

Identifying signs of wear is crucial for determining when to replace components of the Turbocharger Pipe 11427844986. Technicians should look for:

- Discoloration: Changes in color may indicate overheating or damage.

- Surface Pitting: Small pits or corrosion on the surface can weaken the pipe.

- Excessive Play: Movement in the pipe connections may signal wear in the fittings.

When to Replace Components

When replacing components, follow these guidelines:

- Always wear appropriate safety equipment, gloves, and safety glasses.

- Use recommended tools such as gloves, safety glasses, applicable gaskets, bolts, clamps, and fittings.

- Assess the system to determine why the original turbo failed and if additional replacement parts are needed.

- Fill the turbo oil inlet port with clean engine oil prior to mounting the oil feed line.

- Change engine oil and filter before installing the new turbo.

- Ensure oil intake and return lines are clear and in good condition.

- Start the engine without firing until a steady stream of oil flows from the drain port.

- Carefully position the new gasket centered on the exhaust manifold opening.

- Torque studs/bolts to specifications when mounting the turbo.

- Allow the engine to idle for at least 3 minutes after installation to ensure proper lubrication.

By adhering to these maintenance tips, technicians can ensure the longevity and performance of the Turbocharger Pipe 11427844986.

Performance Optimization

Enhancing Efficiency

To optimize the performance of the Turbocharger Pipe 11427844986, technicians should consider several strategies. One effective method involves using high-performance replacement turbo charge air pipes. These pipes are engineered to withstand high temperatures and harsh conditions, significantly enhancing the overall performance and longevity of the Turbocharger Pipe 11427844986.

Additionally, regular maintenance plays a crucial role in ensuring efficiency. Technicians should routinely check for leaks, cracks, and other signs of wear. Addressing these issues promptly can prevent further damage and maintain optimal airflow.

Another strategy involves upgrading to a larger diameter pipe. A larger pipe can improve airflow, allowing the turbocharger to operate more efficiently. This modification can lead to better throttle response and increased power output.

Common Issues and Solutions

Despite best efforts, common issues may arise with the Turbocharger Pipe 11427844986. Understanding these problems and their solutions can help maintain performance.

- Boost Leaks: Boost leaks occur when there is a break in the air delivery system. This issue can lead to reduced power and efficiency. To resolve this, technicians should inspect all connections and hoses for signs of wear or damage. Replacing faulty components can restore proper function.

- Overheating: Overheating can damage the turbocharger and associated components. Ensuring proper cooling and lubrication is essential. Technicians should regularly check coolant levels and oil quality. If overheating persists, it may be necessary to evaluate the entire cooling system for potential issues.

- Clogged Pipes: Clogged pipes can restrict airflow, leading to decreased performance. Regular cleaning of the Turbocharger Pipe 11427844986 is vital. Technicians should use appropriate cleaning solutions and methods to remove any buildup that may hinder airflow.

- Worn Seals: Worn seals can lead to air leaks, affecting performance. Technicians should inspect seals during routine maintenance and replace any that show signs of wear. This proactive approach can prevent larger issues down the line.

By implementing these strategies and addressing common issues, technicians can significantly enhance the performance of the Turbocharger Pipe 11427844986. Regular maintenance and timely repairs ensure that the turbocharger operates efficiently, ultimately leading to improved vehicle performance.

Using the right tools for servicing the Turbocharger Pipe 11427844986 is essential for maintaining optimal performance. Quality tools not only enhance the efficiency of repairs but also contribute to the longevity of the turbocharger system. Investing in OE quality replacement parts, such as those from Rein Automotive, ensures durability and performance, ultimately reducing long-term maintenance costs. Technicians should prioritize quality in their tool selection to achieve the best results and avoid costly repairs in the future.

FAQ

What is the Turbocharger Pipe 11427844986?

The Turbocharger Pipe 11427844986 is a crucial component in turbocharged engines. It channels compressed air from the turbocharger to the engine, enhancing performance and efficiency.

How often should I inspect the Turbocharger Pipe?

Inspect the Turbocharger Pipe at least every 5,000 miles or every six months. Regular checks help identify potential issues early, preventing costly repairs.

What tools do I need for servicing the Turbocharger Pipe?

Essential tools include wrenches, socket sets, torque wrenches, pliers, and screwdrivers. Specialized tools like pipe cutters and inspection cameras can also enhance maintenance efficiency.

How can I tell if the Turbocharger Pipe needs replacement?

Signs of wear include discoloration, surface pitting, and excessive play in connections. If you notice these issues, consider replacing the pipe to maintain performance.

What cleaning methods are recommended for the Turbocharger Pipe?

Use wet cleaning for four-stroke engines and dry cleaning for two-stroke engines. Follow the recommended frequency and methods to ensure optimal performance.

Can I use aftermarket parts for the Turbocharger Pipe?

Yes, aftermarket parts can be used, but ensure they meet OEM specifications. Quality aftermarket parts can provide similar performance and durability as original equipment.

What are common issues with the Turbocharger Pipe?

Common issues include boost leaks, overheating, clogged pipes, and worn seals. Regular maintenance and prompt repairs can help mitigate these problems.

How does proper maintenance affect turbocharger performance?

Proper maintenance enhances turbocharger performance by ensuring efficient airflow and preventing leaks. This leads to improved throttle response and overall engine efficiency.

Post time: Oct-08-2025