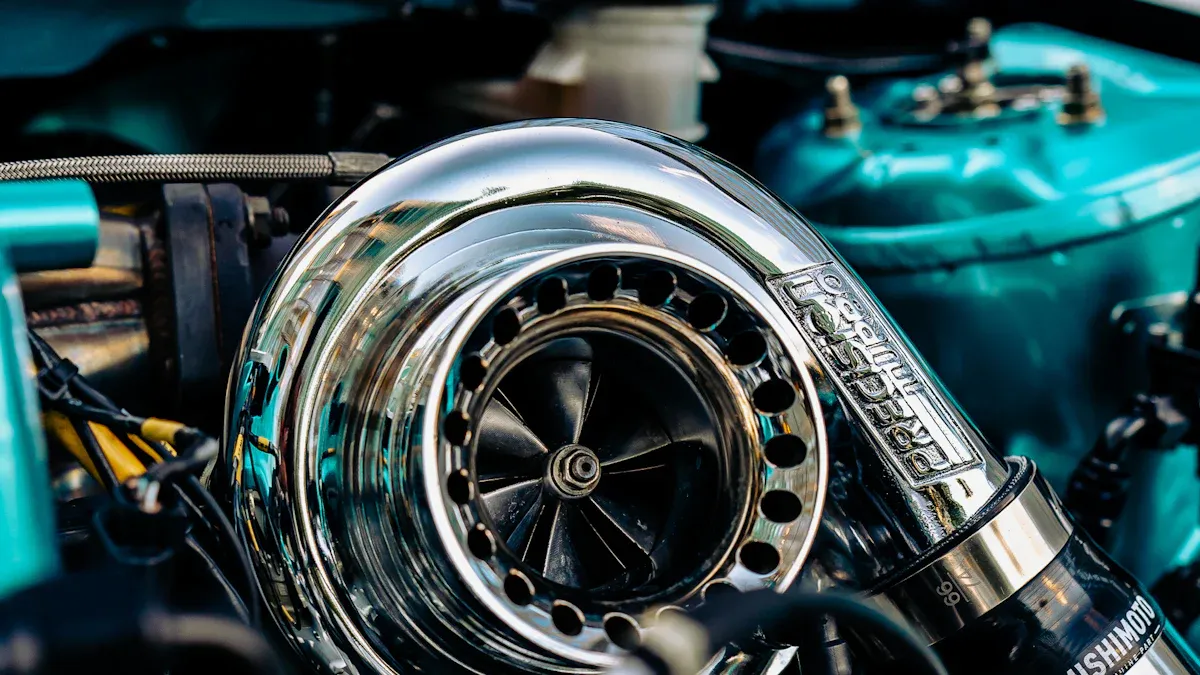

Turbocharger pipes play a critical role in maximizing engine performance. By channeling compressed air efficiently, these components help deliver more power and sharper throttle response. Recent automotive research highlights that optimizing turbocharger system components, such as wheel design, can increase turbine matching efficiency by up to 4.7%. This improvement allows engines to achieve higher power density and better fuel efficiency. When engineers select the right turbocharger pipe, they support consistent airflow, reduced turbo lag, and enhanced reliability for modern engines.

Quality turbocharger pipes contribute to engine downsizing and lower emissions, making them essential for today’s performance vehicles.

Key Takeaways

- Turbocharger pipes direct compressed air to the engine, increasing oxygen for better power and efficiency.

- Upgrading to smooth, larger-diameter pipes reduces airflow resistance, boosting horsepower and throttle response.

- Durable materials like stainless steel and aluminum improve pipe strength, heat resistance, and long-term reliability.

- Shorter, straighter pipe designs help reduce turbo lag by delivering boost pressure faster to the engine.

- Well-sealed pipes prevent boost leaks, protecting engine parts and maintaining consistent power delivery.

- Optimized airflow through quality pipes supports better fuel combustion, improving fuel economy and lowering emissions.

- Regular inspection and cleaning of turbocharger pipes prevent leaks and damage, ensuring steady engine performance.

- Aftermarket pipes offer significant performance gains for tuned or high-boost engines, while OEM pipes suit stock setups.

Turbocharger Pipe: What It Is and How It Works

Definition and Main Function

Role in Airflow and Boost Delivery

A turbocharger pipe serves as a vital conduit in forced induction systems. It directs compressed air from the turbocharger’s compressor to the engine’s intake manifold. This pathway ensures that the engine receives a steady supply of high-pressure air, which increases the amount of oxygen available for combustion. More oxygen allows the engine to burn more fuel, resulting in greater power output and improved efficiency.

Efficient airflow through the turbocharger pipe reduces resistance, helping the turbocharger deliver boost quickly and consistently. This design supports rapid throttle response and minimizes turbo lag, which is the delay between pressing the accelerator and feeling the engine’s increased power.

Connection Between Turbocharger, Intercooler, and Engine

Turbocharger pipes connect several key components within the turbocharging system. These include the turbocharger itself, the intercooler, and the engine. The system operates as follows:

- The turbocharger compresses intake air, increasing its pressure and temperature.

- The boost pipe carries this hot, pressurized air to the intercooler.

- The intercooler cools the air, making it denser for better combustion.

- The charge pipe then delivers the cooled, compressed air to the engine’s intake manifold.

Other essential components, such as the wastegate and blow-off valve, regulate boost pressure and protect the system from surges. The pipes must withstand both high temperatures and pressures, ensuring reliable operation under demanding conditions.

Materials and Construction

Common Materials Used

Manufacturers select materials for turbocharger pipes based on their ability to handle heat, pressure, and mechanical stress. The most common materials include:

| Material | Key Properties | Effect on Turbocharger Performance |

|---|---|---|

| Stainless Steel | Rust and corrosion resistant, high strength, excellent thermal resistance | Ideal for harsh, high-temperature environments; ensures durability and structural integrity under stress |

| Cast Iron | Durable, excellent heat retention, affordable | Maintains high exhaust gas temperatures improving efficiency; withstands mechanical stress and thermal cycling |

| Aluminum | Lightweight, good thermal conductivity | Reduces overall system weight; aids heat dissipation; adequate for performance applications |

Each material offers unique benefits. Stainless steel provides exceptional durability in high-heat environments. Cast iron retains heat and resists thermal cycling, making it suitable for exhaust components. Aluminum’s lightweight nature helps reduce vehicle weight and improves heat dissipation.

Importance of Durability and Pressure Resistance

Durability and pressure resistance are critical for turbocharger pipes. High-quality materials prevent failures such as thermal cracking, fatigue, and leaks. Pipes must withstand rapid temperature changes and high boost pressures without deforming or failing. Reinforced construction and heat-resistant alloys ensure long-lasting performance, even under extreme driving conditions. Reliable turbocharger pipes help maintain consistent airflow, reduce back pressure, and support optimal engine performance over time.

Turbocharger Pipe and Airflow Improvement

Smoother, Less Restrictive Pathways

Reducing Airflow Resistance

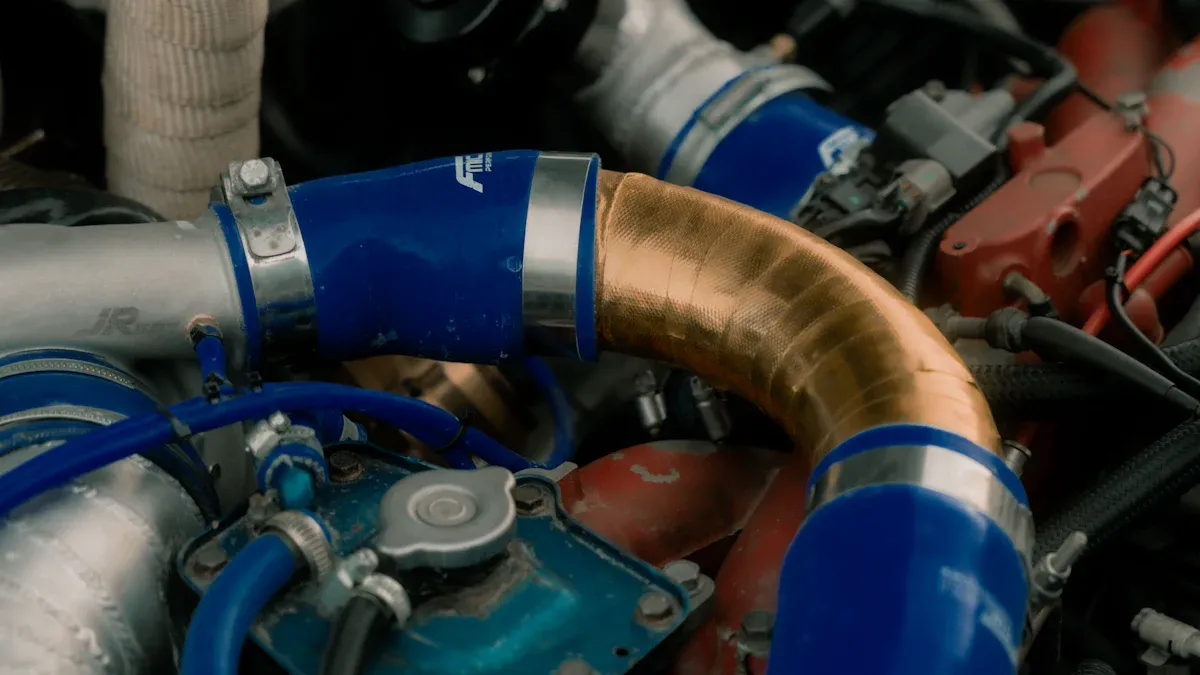

Engineers design modern turbocharger pipes to minimize bends and restrictions, creating a direct path for compressed air. Factory charge pipes often use plastic materials and feature narrow, uneven pathways. These characteristics cause pressure loss and retain heat, which reduces the efficiency of turbocharged airflow. Upgrading to mandrel-bent aluminum pipes increases the diameter and smoothness of the pathway. This improvement reduces pressure loss and allows air to move more freely from the turbo to the intercooler and intake manifold.

Smoother, less restrictive pipes accelerate airflow, which enhances throttle response and increases horsepower. Durable materials like aluminum also prevent frequent replacements, ensuring consistent performance over time.

Example: Upgrading Stock Pipes for Better Flow

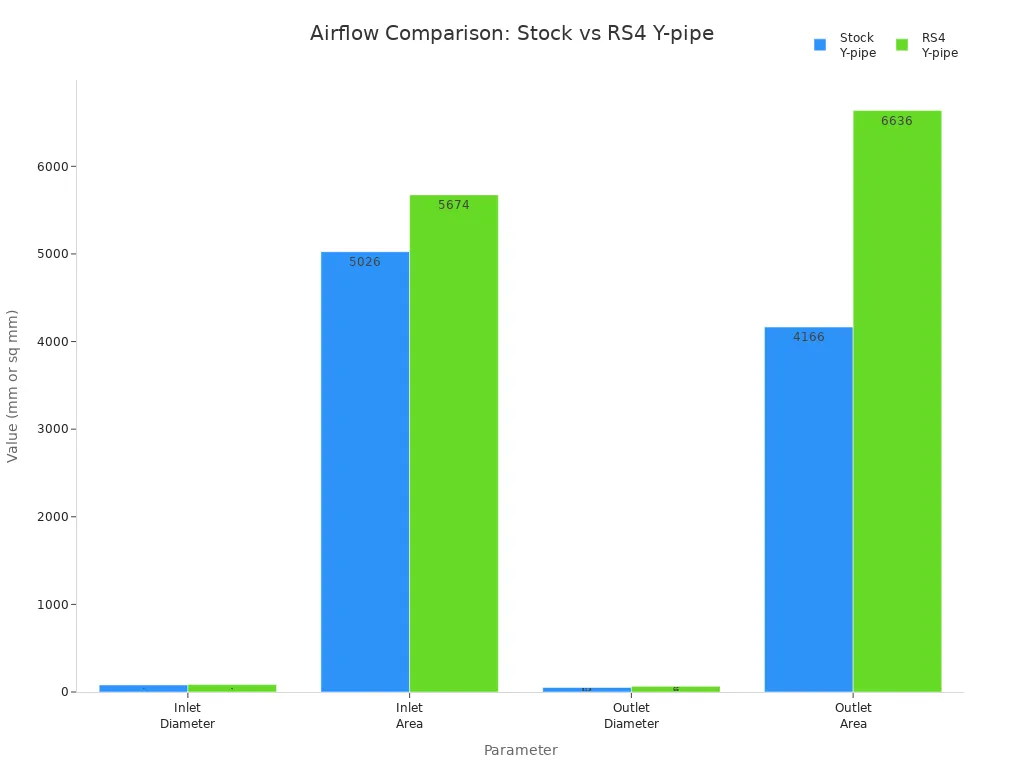

Controlled flow bench tests highlight the benefits of performance turbocharger pipes. The RS4 Y-pipe, for example, features a larger inlet and outlet area compared to the stock Y-pipe. This design reduces pressure losses by up to 0.5 psi at higher airflow rates, which is especially important for vehicles running higher boost levels. The table below compares the airflow characteristics of stock and RS4 Y-pipes:

| Parameter | Stock Y-pipe | RS4 Y-pipe |

|---|---|---|

| Inlet Diameter (mm) | 80 | 85 |

| Inlet Cross-sectional Area (sq mm) | 5026 | 5674 |

| Combined Outlet Diameter (mm) | 51.5 (each outlet) | 65 (each outlet) |

| Combined Outlet Area (sq mm) | 4166 (83% of inlet) | 6636 (117% of inlet) |

| Pressure Loss Reduction at High CFM | Baseline | Up to 0.5 psi less |

Maximizing Oxygen for Combustion

Impact on Engine Power Output

Turbocharger pipe design directly affects the amount of oxygen delivered to the engine. Stock inlet pipes often restrict airflow, limiting the oxygen available for combustion. Upgraded pipes can increase airflow volume by about 50%, enabling the turbocharger to spool faster and operate more efficiently. More oxygen-rich air reaches the engine, allowing it to burn more fuel and generate more power. Proper pipe design ensures smooth, unrestricted airflow, which improves both low-end power and overall engine performance.

- Turbocharger inlet pipe design influences airflow and oxygen delivery.

- Restrictive stock pipes limit performance.

- Upgraded pipes increase airflow and turbo efficiency.

- More oxygen supports higher fuel burn and power output.

- Smooth pipe design improves engine response and durability.

Real-World Performance Gains

Aftermarket aluminum charge pipes have demonstrated significant improvements in real-world tests. For example, a 2.3L turbocharged Bronco showed up to 9% increased airflow on the hot side and nearly 70% more on the cold side after replacing stock pipes. These upgrades improved airflow consistency, turbo spool, throttle response, and engine efficiency. Users also report better power delivery and minimal turbo lag, especially when targeting higher horsepower levels. Performance downpipes further reduce restrictions, improving quarter-mile times by approximately 0.2 seconds. These results confirm that upgrading turbocharger pipes leads to measurable gains in both power and drivability.

Turbocharger Pipe and Turbo Lag Reduction

Faster Air Delivery to the Engine

Shorter, More Direct Routing

Turbo lag occurs when there is a delay between pressing the accelerator and feeling the engine’s increased power. Engineers address this issue by designing turbocharger pipes with shorter and more direct routing. A direct path allows compressed air to reach the engine intake faster, reducing the time it takes for the turbocharger to deliver boost. This approach minimizes the distance air must travel, which helps the engine respond more quickly to driver input.

Modern turbocharger pipe systems incorporate several advanced design features to optimize air delivery:

- Precise engineering of pipe lengths and angles reduces performance losses by creating efficient flow paths.

- Sophisticated piping configurations help maintain air pressure and temperature, ensuring efficient transfer of compressed air.

- Advanced computational fluid dynamics (CFD) modeling allows engineers to optimize airflow and minimize pressure drops.

- Specialized high-temperature materials and precise fabrication techniques maintain system integrity under thermal expansion, vibration, and mechanical stress.

- Thermal management strategies, such as heat shielding and the use of intercoolers, help keep air temperatures low and air density high.

These innovations ensure that the turbocharger pipe delivers air rapidly and efficiently, which directly improves engine responsiveness.

Example: Aftermarket Pipe Designs

Aftermarket manufacturers often develop turbocharger pipes with even shorter and straighter routes than factory-installed systems. These designs use mandrel bends and larger diameters to further reduce restrictions. For example, some performance kits replace multiple factory bends with a single, smooth curve. This change decreases turbulence and pressure loss, allowing the turbocharger to spool up faster. Many enthusiasts report noticeable improvements in throttle response and reduced turbo lag after upgrading to these aftermarket solutions.

Maintaining Consistent Boost Pressure

Preventing Pressure Drops

Consistent boost pressure is essential for optimal engine performance. Turbocharger pipes must prevent pressure drops that can occur due to leaks, poor connections, or restrictive bends. Engineers use advanced materials and precise joining techniques to create airtight seals. They also refine pipe geometry through prototype testing and iterative design, ensuring minimal pressure loss and maximum air density.

Improved Throttle Response

A well-designed turbocharger pipe system maintains steady boost pressure, which leads to sharper throttle response. The engine receives a consistent supply of compressed air, allowing it to react instantly to driver commands. This improvement not only enhances acceleration but also makes the vehicle feel more responsive and enjoyable to drive. By reducing turbo lag and maintaining boost, the turbocharger pipe plays a crucial role in delivering a seamless driving experience.

Turbocharger Pipe and Fuel Efficiency

Optimized Air-Fuel Mixture

Better Combustion Efficiency

Engineers design modern turbocharger systems to deliver denser, cooler air to the engine. By reducing turbulence and restrictions in the airflow, larger diameter piping and smoother pathways allow the turbocharger to compress air more effectively. This process increases the oxygen content per unit volume, which leads to a richer air-fuel mixture. When the engine receives this optimized mixture, combustion becomes more powerful and complete. The result is a significant boost in both engine power and efficiency.

The turbocharger compresses intake air, raising its pressure and density. This denser air carries more oxygen into the combustion chamber. With more oxygen available, the engine can burn fuel more thoroughly, releasing greater energy with each cycle. This efficient combustion not only increases power output but also improves fuel economy and reduces emissions. Heat-resistant materials in turbocharger hoses ensure that compressed air reaches the engine without leaks or losses, maintaining optimal boost pressure and supporting consistent, efficient combustion.

Note: Efficient air delivery supports more complete combustion, which translates into better fuel efficiency and lower emissions.

Example: Daily Driving Benefits

Drivers experience the benefits of optimized air-fuel mixtures during everyday use. Vehicles equipped with upgraded turbocharger piping often show improved throttle response and smoother acceleration. These improvements mean the engine does not need to work as hard to produce the same amount of power. As a result, fuel consumption drops, especially during city driving where frequent acceleration and deceleration occur. Many drivers report that their vehicles feel more responsive and require less fuel to travel the same distance after upgrading their turbocharger pipes.

Supporting Engine Management Systems

Enhanced Sensor Readings

Modern engines rely on a network of sensors to monitor airflow, temperature, and pressure. High-quality turbocharger pipes help maintain stable and predictable airflow, which allows sensors to provide accurate data to the engine control unit (ECU). When the ECU receives reliable information, it can adjust fuel injection and ignition timing more precisely. This precision leads to better combustion control and improved fuel efficiency.

| Sensor Type | Function | Benefit of Stable Airflow |

|---|---|---|

| Mass Air Flow (MAF) | Measures incoming air volume | Accurate fuel delivery |

| Manifold Pressure | Monitors boost pressure | Consistent engine performance |

| Intake Air Temp | Tracks air temperature | Optimized ignition timing |

Smoother Engine Operation

Stable airflow and accurate sensor readings contribute to smoother engine operation. The ECU can make real-time adjustments to maintain the ideal air-fuel ratio, even under changing driving conditions. This adaptability ensures that the engine runs efficiently whether cruising on the highway or navigating stop-and-go traffic. Smoother operation reduces engine strain, extends component life, and helps maintain peak fuel efficiency over time.

Turbocharger Pipe for Higher Boost Levels

Handling Increased Pressure

Stronger Materials and Construction

Performance engines often demand higher boost levels, which place significant stress on the entire charge-air system. Engineers address these challenges by selecting robust materials and advanced construction techniques. Cast aluminum and high-grade silicone have become the preferred choices for modern performance upgrades. Cast aluminum charge pipes replace fragile plastic components, eliminating the risk of cracks and failures when subjected to elevated boost pressures. Silicone hoses outperform traditional rubber by resisting both heat and pressure, ensuring long-term reliability.

CNC-machined adapters at turbo and throttle connections provide a precise, leak-free fit. Serrated adapters further secure hoses, preventing them from blowing off during aggressive acceleration. These enhancements allow the system to withstand the intense demands of high-performance driving.

Example: Performance Upgrades

Many aftermarket kits showcase these improvements. For example, a performance upgrade might include a cast aluminum charge pipe, silicone couplers, and CNC-machined adapters. These components work together to create a seamless, high-strength pathway for compressed air. Optimized transitions between pipes reduce turbulence and support higher airflow rates. Drivers who install these upgrades often report increased boost stability and improved throttle response, especially when pushing their engines beyond factory specifications.

Preventing Pipe Expansion and Leaks

Maintaining Consistent Boost

Boost leaks represent the most common failure point in high-pressure turbo systems. These leaks often occur at connections, couplers, or clamps. When a leak develops, the turbo must work harder to maintain target boost, which can lead to overspeeding and increased backpressure. To prevent these issues, engineers use several strategies:

- Replace plastic and rubber pipes with cast aluminum and silicone for superior strength.

- Use CNC-machined adapters for tight, reliable connections.

- Install serrated adapters to keep hoses securely in place.

- Optimize pipe transitions to minimize flow restrictions and reduce the risk of leaks.

Routine inspection and proper installation of clamps also play a crucial role. Crooked, oversized, or loose clamps frequently cause leaks. Simple adjustments, such as reorienting or tightening clamps, can restore proper sealing and boost performance.

Protecting Engine Components

Consistent boost pressure not only improves power delivery but also protects vital engine components. When leaks occur, air escapes between the turbo and intake manifold. Even small leaks force the turbo to spin faster, increasing wear and the risk of damage. Common failure points include loose-fitting silicone couplers and improperly seated clamps. Technicians often use smoke tests or soapy water sprays to detect leaks quickly. Addressing these issues promptly helps maintain engine reliability and ensures the turbo system operates at peak efficiency.

Turbocharger Pipe and Engine Reliability

Reducing Heat Soak and Mechanical Stress

Use of Heat-Resistant Materials

Engineers address heat soak and mechanical stress in high-performance engines by carefully selecting materials and optimizing pipe design. They often position the turbocharger away from the crowded engine bay, sometimes mounting it at the rear of the vehicle. This placement exposes the turbo components to cooler ambient air, which helps dissipate heat more effectively. Extended piping increases the distance from primary heat sources, providing better thermal isolation and reducing thermal stress on critical parts.

Specialized materials and advanced insulation techniques play a crucial role in maintaining structural integrity. Stainless steel, cast iron, and advanced alloys resist high temperatures and mechanical fatigue. Engineers also use computational fluid dynamics (CFD) to optimize pipe routing, ensuring that lengths, angles, and bends manage thermal expansion and vibration. These strategies collectively preserve system reliability and protect surrounding engine components from excessive heat.

Note: Lower under-hood temperatures not only safeguard the turbo system but also improve the longevity and performance of nearby engine parts.

Example: Long-Term Durability

Long-term durability of turbocharger pipes depends heavily on material selection and testing. Scientific studies on steel pipes, such as P92, show that prolonged exposure to stress and heat can cause microstructural changes. Over time, these changes degrade mechanical properties like tensile strength and creep life, especially under elevated stress. Manufacturers like Mitsubishi Heavy Industries conduct rigorous thermo cycling tests, repeatedly exposing turbine housing materials to extreme temperature fluctuations. These tests reveal how materials such as steel, iron, and aluminum withstand cracking, warping, or deformation over hundreds of hours. The results guide engineers in choosing materials that balance durability, cost, and regulatory requirements.

Recent innovations focus on lightweight composites and advanced alloys. These materials offer improved resistance to heat and mechanical stress, meeting the demands of modern engines and stricter emission standards.

Preventing Contaminant Ingress

Sealed Connections

Sealed connections in turbocharger systems play a vital role in protecting engine reliability. Engineers use specialized seals and hose assemblies designed to withstand extreme temperatures, chemical exposure, and pressure changes. These seals form tight barriers that prevent dust, moisture, and debris from entering the system. Materials such as silicone and custom gaskets provide durability and chemical resistance, ensuring leak-free performance even in harsh environments.

Labyrinth seals offer an additional layer of protection. Their complex, maze-like design forces contaminants to navigate a difficult path, significantly reducing the risk of dust or moisture reaching sensitive engine parts. These non-contacting seals maintain their effectiveness over time, as they do not wear out quickly. The design also induces turbulent flow and centrifugal forces, repelling unwanted particles while retaining necessary fluids inside the system.

Protecting Sensitive Engine Parts

Maintaining clean airflow and fluid flow is essential for engine health. Sealed turbocharger pipe connections reduce the risk of corrosion, wear, and mechanical failure by keeping contaminants out. This protection extends the lifespan of sensitive engine components, such as sensors and moving parts, and ensures reliable operation under demanding conditions. By preventing the ingress of harmful particles, engineers help maintain optimal engine performance and reduce the likelihood of premature failures.

Tip: Regular inspection of seals and connections helps ensure continued protection against contaminants, supporting long-term engine reliability.

Choosing and Maintaining Turbocharger Pipes

OEM vs. Aftermarket Turbocharger Pipes

Pros and Cons of Each Option

Vehicle owners often face a choice between OEM and aftermarket turbocharger pipes. OEM pipes come designed for reliability and compatibility with factory specifications. They typically use rubber or plastic materials, which help reduce heat retention but can restrict airflow. These pipes perform well for daily driving and mild modifications, offering a cost-effective solution for most users.

Aftermarket pipes, on the other hand, focus on maximizing performance. Manufacturers use stainless steel or aluminum, increasing pipe diameter and reducing bends. These improvements enhance airflow and minimize heat soak, especially in high-performance applications. For example, bench flow testing and dyno results show that aftermarket pipes with heat-reflective coatings can deliver measurable power gains, particularly on tuned engines. However, aftermarket options often cost more and may require professional installation.

Note: OEM pipes suit stock or lightly modified vehicles, while aftermarket pipes excel in aggressive tuning scenarios.

| Feature | OEM Pipes | Aftermarket Pipes |

|---|---|---|

| Material | Rubber/Plastic | Stainless Steel/Aluminum |

| Airflow | Moderate | High |

| Heat Management | Good (less heat retention) | Excellent (with coatings) |

| Cost | Lower | Higher |

| Best For | Stock/Mildly tuned cars | High-performance builds |

When to Consider an Upgrade

Drivers should consider upgrading to aftermarket pipes when seeking higher horsepower or planning advanced tuning. OEM pipes may become a bottleneck as power levels rise, especially above 400 horsepower. Aftermarket solutions provide better airflow and heat rejection, supporting reliable performance at elevated boost pressures. For those who drive aggressively or participate in motorsports, an upgrade ensures the engine receives optimal airflow and maintains consistent power delivery.

Maintenance Tips for Turbocharger Pipes

Regular Inspection and Signs of Wear

Routine inspection helps prevent costly failures. Technicians recommend checking turbocharger pipes and hoses every 15,000 miles. Look for oil leaks around connections, which may indicate worn seals or gaskets. Loss of boost pressure, unusual noises like whistling or whining, and visible cracks or corrosion signal potential issues. Regularly inspect air filters and intake tubes to prevent debris from damaging turbo components. Early detection of these signs allows for timely repairs and protects engine health.

- Oil leaks near turbo seals

- Whistling or whining noises

- Reduced boost pressure or poor acceleration

- Physical damage such as cracks or corrosion

Cleaning and Extending Pipe Lifespan

Proper cleaning and maintenance extend the life of turbocharger pipes. Clean the intercooler and related piping regularly to remove debris and prevent heat soak. Pressure test the system annually to detect leaks. Ensure all connections remain tight and properly sealed. Use high-quality synthetic oils and filters to protect turbo components. Allow the engine to warm up before driving and cool down after heavy use to maintain oil flow and prevent overheating. Follow manufacturer maintenance intervals, replacing hoses and gaskets every 30,000 miles or 36 months for optimal reliability.

Tip: Consistent maintenance not only preserves performance but also reduces the risk of unexpected breakdowns.

Turbocharger pipes play a crucial role in maximizing engine power, efficiency, and reliability. Upgrading to high-quality pipes improves airflow, reduces turbo lag, and enhances throttle response. Regular inspection and cleaning prevent leaks and debris buildup, supporting long-term engine health. Automotive experts recommend replacing restrictive stock pipes with durable materials like aluminum to achieve consistent performance gains. Prioritizing turbocharger pipe upgrades ensures smoother operation, increased horsepower, and better fuel economy for any turbocharged vehicle.

FAQ

What is the main purpose of a turbocharger pipe?

A turbocharger pipe channels compressed air from the turbocharger to the engine. This process increases the oxygen available for combustion. The result is improved engine power and efficiency.

How often should drivers inspect turbocharger pipes?

Technicians recommend inspecting turbocharger pipes every 15,000 miles. Regular checks help identify leaks, cracks, or loose connections early. Early detection prevents performance loss and protects engine components.

Can aftermarket turbocharger pipes improve performance?

Aftermarket turbocharger pipes often use larger diameters and smoother bends. These features reduce airflow restrictions. Many drivers report better throttle response and increased horsepower after upgrading.

What materials offer the best durability for turbocharger pipes?

Stainless steel, cast aluminum, and high-grade silicone provide excellent durability. These materials resist heat, pressure, and mechanical stress. They help maintain consistent boost and extend the lifespan of the turbo system.

How do turbocharger pipes affect fuel efficiency?

Efficient turbocharger pipes deliver denser, cooler air to the engine. This process supports better combustion. Improved combustion leads to higher fuel efficiency and lower emissions.

What are signs of a failing turbocharger pipe?

Common signs include oil leaks, whistling noises, reduced boost pressure, and visible cracks. Drivers may also notice poor acceleration. Immediate attention to these symptoms prevents further engine damage.

Do turbocharger pipes require special maintenance?

Routine cleaning and inspection keep turbocharger pipes in top condition. Technicians recommend pressure testing the system annually. Tightening connections and replacing worn seals also help maintain performance.

When should drivers consider upgrading turbocharger pipes?

Drivers should consider upgrades when increasing boost levels or modifying the engine for more power. Performance pipes support higher airflow and boost stability. Upgrades benefit both daily drivers and motorsport enthusiasts.

Post time: Aug-08-2025